Tailored for Every Sector

Traditional manual methods are slow, dangerous, and inconsistent. Our autonomous fleet revolutionizes maintenance across three critical sectors, delivering precision that human hands simply cannot match.

Buildings & Structures

Automated facade cleaning and inspection for skyscrapers and complex structures. Eliminating human risk at extreme heights while delivering consistent, streak-free results.

Precision Cleaning

Touchless high-pressure washing

Visual Inspection

AI-driven defect detection

Surface Coating

Protective sealant application

Why Automation is Non-Negotiable

Manual infrastructure maintenance is dangerous, slow, and legally risky.

Fatal Safety Risks

Fatalities in US, China, and Korea (2011-2020) due to falls and accidents.

Legal Liability

CEOs and owners face imprisonment under new Serious Accident Punishment Acts.

Soaring Costs

Average cost for manual cleaning of a single 25-story building.

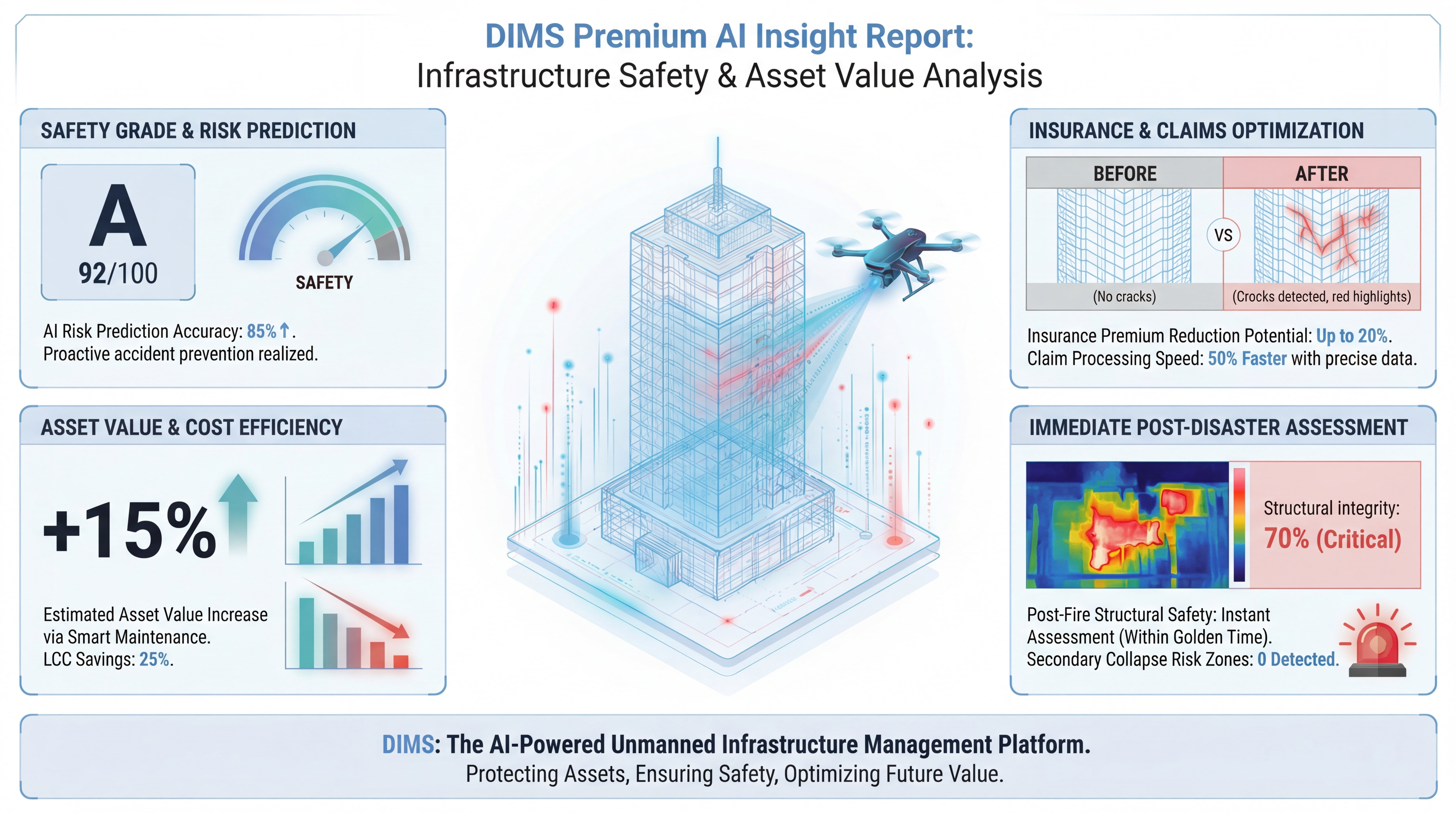

Safety & Risk Assessment

Advanced structural analysis and automated safety grading for aging infrastructure.

Automated Grading

Asset Value

Disaster Analysis

Insurance Data

Real-time Risk

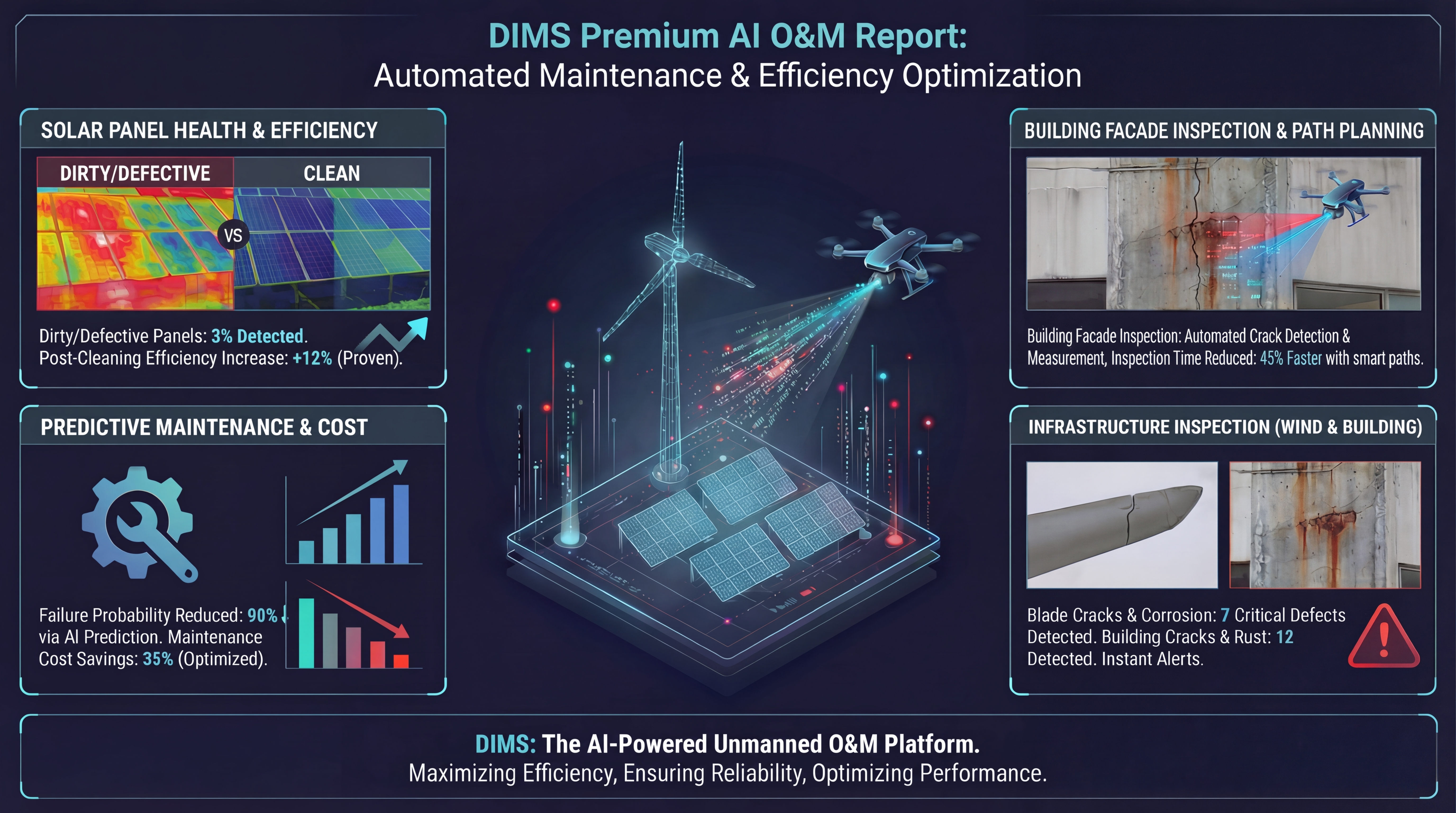

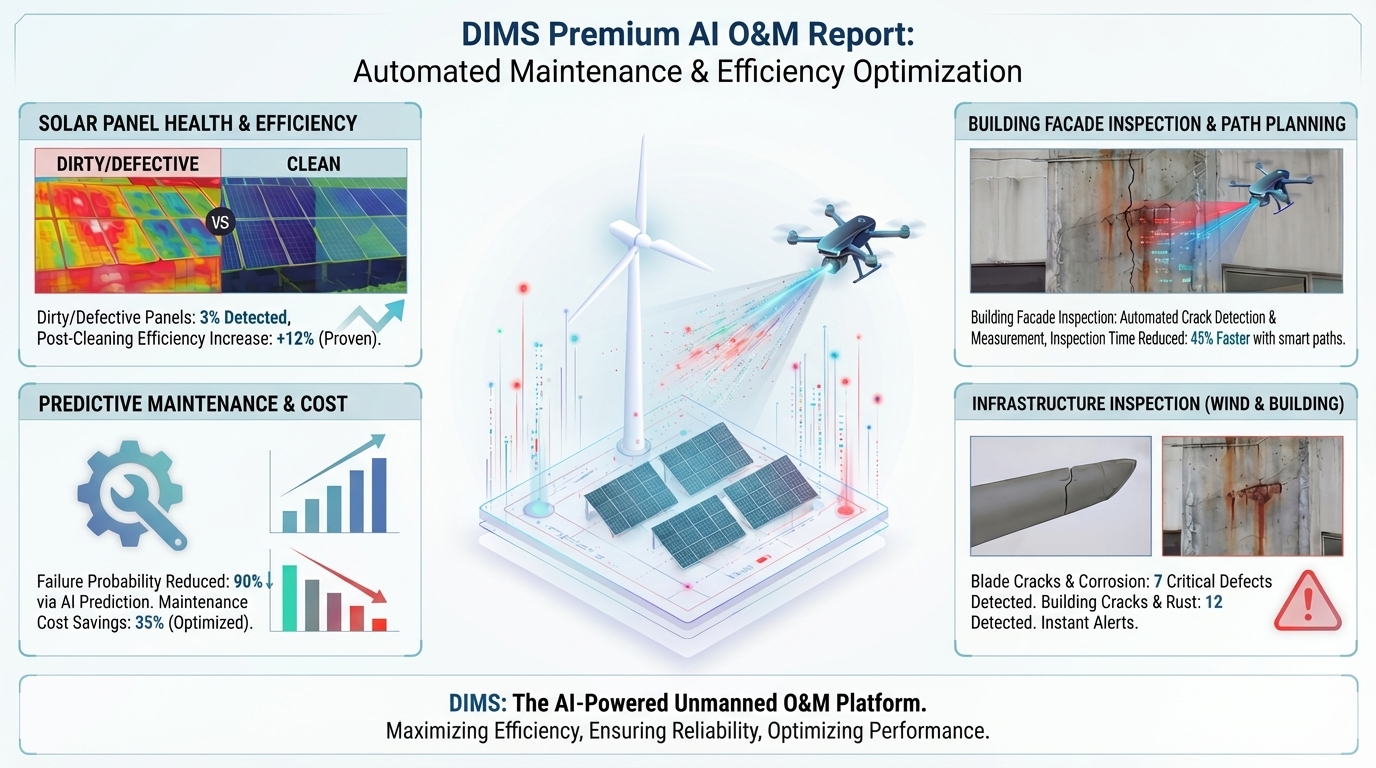

Automated O&M

Maximizing efficiency with AI-driven maintenance and failure prediction.

Solar Analysis

Efficiency Boost

Cost Optimization

Smart Pathing

Crack Detection

Unmatched Efficiency.

Proven Results.

We benchmarked DIMS against manual labor on a standard 25-story high-rise (10,500m²). The results speak for themselves.

Performance Benchmark

Efficiency comparison based on standard deployment.

Total Cost

Time Efficiency

Market Validation

Trusted by industry leaders with proven deployment success.

Strategic Partners

Ecosystem

Leadership Team

Engineered by experts from KAIST, DJI, and POSCO.

Jung-Hyun Ahn

Ex-DJI Global Enterprise.

Former CEO of cleaning robotics co.

Faizan

KAIST Aerospace & CS Double Major. Expert in Computer Vision AI & Flight Control Algorithms.

Haruna

KAIST Aerospace M.S. & Ph.D. Designs drone control systems and cloud platform architecture.

Changmo

POSCO Alumnus, Ph.D. in Architecture. Leads building inspection design & process optimization.

Haibo

Expert in international trade & global partnerships. Leads overseas business operations and export strategy.